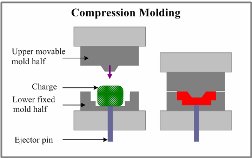

OVERVIEW of Compression Molding (definition) |

Compression molding of plastics

A method of molding in which the molding material, generally preheated, is first placed in an open, heated mold cavity. The mold is closed with a top force or plug member, pressure is applied to force the material into contact with all mold areas, and heat and pressure are maintained until the molding material has cured. The process employs thermosetting resins in a partially cured stage, either in the form of granules, putty-like masses, or preforms. Compression molding is a high-volume, high-pressure method suitable for molding complex, high-strength fiberglass reinforcements. Advanced composite thermoplastics can also be compression molded with unidirectional tapes, woven fabrics, randomly orientated fiber mat or chopped strand. The advantage of compression molding is its ability to mold large, fairly intricate parts. Compression molding produces fewer knit lines and less fiber-length degradation than injection molding.

|

|

![Compression Molding (definition) Compression Molding (definition)]()

|